We produce quality on these machines

QUALITY

To ensure the highest quality, we use metrology equipment from the leading manufacturers in their field. During the selection process, we attach particular importance to reliably stable measurement results that are independent of the operator.

| Type | Manufacturer | Model |

| 3D measuring machine | Zeiss | Duramax |

| Projector | Keyence | IM-7020 |

| Contour measuring system | Accretech | Surfcom 1800G |

| Surface measuring system | Accretech | Surfcom 1800G |

| 3D scanner for external geometry | Jenoptik | CS155 Pro |

| HRC hardness tester | Mitutoyo | HR-320MS |

| HV hardness tester | Innovatest | Falcon 403 |

| CAQ & SPC software | Synfactory | |

| Optical sorting system for shafts | Custom machine for Dakoko | |

| 100% length & diameter control for shafts | Custom machine for Dakoko | |

| 100% hardness test using eddy current | Custom machine for Dakoko | |

| Optical sorting system for turned parts with vibratory conveyor | Custom machine for Dakoko | |

| Optical sorting system for sensitive turned parts with robot feed | Custom machine for Dakoko |

CNC SLIDING HEADSTOCK LATHES

For stock up to 26 mm and up to 6-axis machining (Tsugami)

- Optimal cycle times and optimal machining precision

- Maximum precision thanks to stationary tools and movable workpiece

- Ideal for medium part volumes up to approx. 300,000 units per year, when high precision and multiple machining steps are required

- Complex back machining on the same machine minimizes faults caused by manual reclamping

| Manufacturer | Model | Quantity |

| Tsugami | BO203 | 3 |

| Tsugami | BO205 | 21 |

| Tsugami | BM165 | 1 |

| Star | SB-20R | 1 |

| Tsugami | BO265 | 3 |

| Tsugami | BO206 | 2 |

| Tsugami | BO204 | 2 |

CNC machining centers & turret lathes

We manufacture large turned parts, milled parts and complex parts that cannot be produced on lathes alone using state-of-the-art machines for complex components.

| Manufacturer | Model | Quantity |

| Mazak | HCN-4000L Horizontal 4-axis machining center with interior cooling | 1 |

| Mazak | QT-100 ML turret lathe with center | 1 |

| Tsugami | M08-SY turret lathe with counter spindle | 1 |

| Tsugami | VA3, 3-axis milling center | 2 |

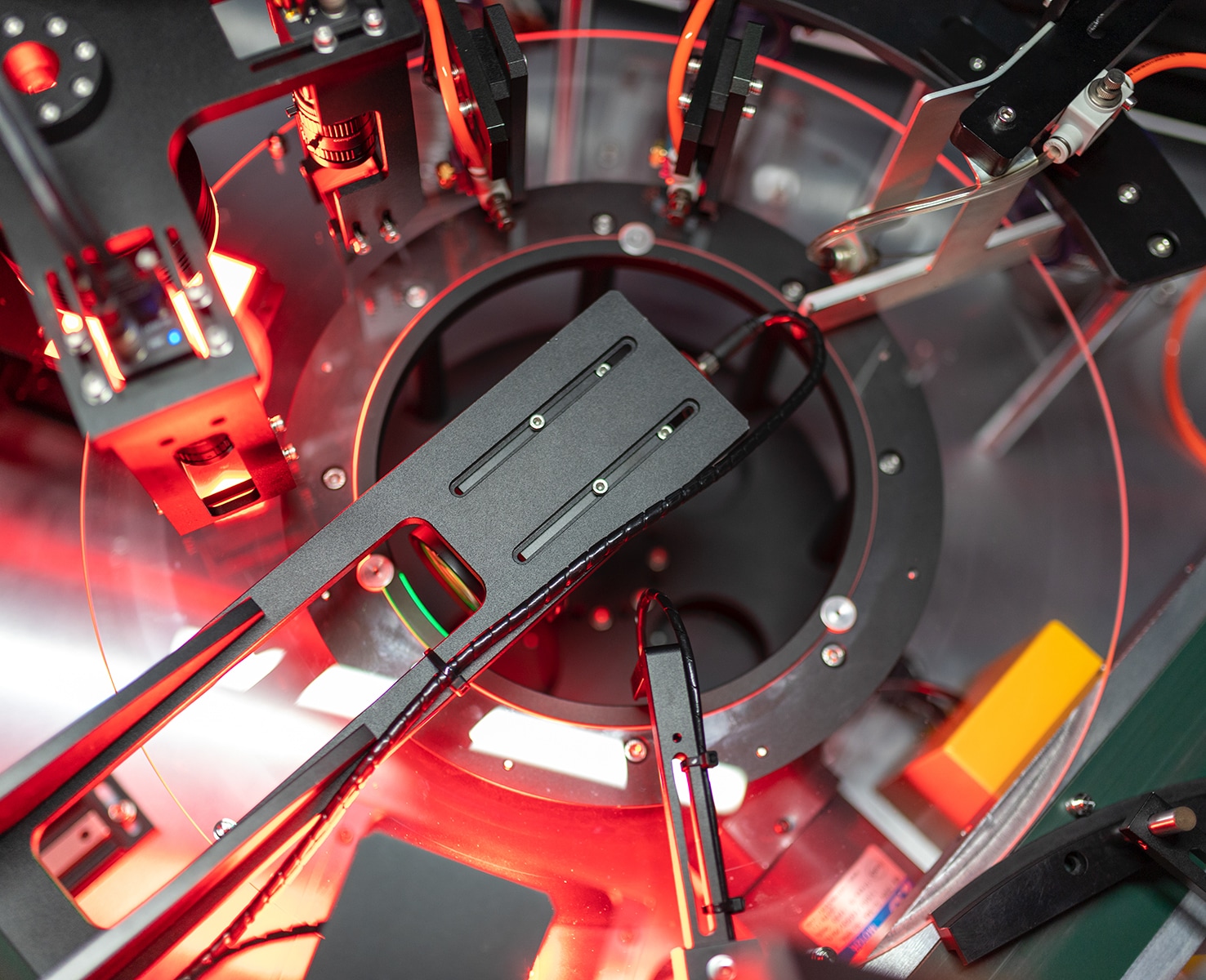

ROTARY TRANSFER TABLE

Rotary transfer system with 8 clamping stations

- Low machining times thanks to driven tools and stationary workpiece

- Non-productive times of only 0.3 seconds – making cycle times of less than 2 seconds possible

- For highly-complex parts and extensive internal machining

- Ideal for high part volumes of more than 250,000 units per year

- Production directly from ring material to reduce material costs

| Manufacturer | Model | Quantity |

|---|---|---|

| Wolf | TSM280 | 3 |

FINISHING

To meet the most demanding requirements while reducing machining times, Dakoko uses special machine types for the final machining steps. The result is consistently impressive part quality at minimal cost.

| Machine type | Manufacturer | Model | Quantity |

| Centerless grinding machine | Palmary | PC-18S | 1 |

| CNC centerless grinding machine with robot loading for inserts | Palmary | PC-12S CNC | 1 |

| Centerless grinding machine | Palmary | PC-12S | 6 |

| Thread rolling machine for components with internal bore | Fuh Der Yang | FDY-30A | 1 |

| Thread rolling machine for components without internal bore | Fuh Der Yang | FDK-30A | 1 |

| Hard lathe for precision turning | Tsugami | C300 | 1 |

| Single-chamber washing system for component cleanliness from 200 µm | Keweixin | 1 |

Convincing advice.

Convincing quality.

Convincing prices.

Dakoko fits.

Let’s talk about your project!

Make use of our extensive experience to discover new solutions to the challenges you face.

Call now: +49 176 8 12345 14

Email: INFO@DAKOKO.COM